Learning Outcomes

After this course learners will be able to:

- Describe the steps for 3D printing an ear mold in-clinic.

- List the reasons why same-day ear molds can benefit your patients.

- Summarize the benefits that an open-source, digital solution to same-day ear molds has over traditionally made instant ear molds.

Introduction

We often hear a lot about meeting best practice guidelines in audiology. In the AudiologyOnline course, The Hearing Aid Test Drive: A Whole-Practice Approach For The New Consumer, Bill Diles and his colleagues (2020) questioned what exactly are best practices in audiology. Most believe that real ear measurements and speech-in-noise testing are considered best practices, but what about same-day emergency appointments, weekend availability, or same-day ear molds? These services and features are definitely beneficial to patients, and ought to be considered as best practices, too. Unfortunately, these services are often forgotten when discussing what best practices are in audiology. Previous to reading this article, I offered most of these useful features at my clinic, but I did not have an effective solution for same-day ear molds. I’m always trying to find innovative and useful ways to meet my patient’s hearing needs, and same-day ear molds can provide so many great benefits to my patients, so I set out to develop a new open-source method for making these products in-house.

What is a same-day ear mold?

A same-day ear mold is a type of mold that can be made for a patient within the same day of requesting for one. These types of molds are sometimes referred to as instant molds. Usually, in order to make ear molds for a patient, ear impressions are taken of the patient’s ears and mailed to an ear mold lab, then the molds are created at the lab and sent back to the clinic for fitting. This whole process takes around one to two weeks. Recent advancements in ear impression technology have streamlined this process with ear scanners to avoid taking physical ear impressions, but the process still takes around a week to receive the end product ear molds in clinic. Also, if further adjustments and fit modifications are required for the ear molds, even more additional shipping time and processing time is added on. Professional ear mold labs make great products, but a downside to their process is the waiting and turn-around time. Patients are often left without appropriately fitting devices while they wait for ear molds.

A same-day ear mold would help a patient hear while waiting for a mold to be made from the lab. Whether it’s a repair on a current ear mold, or a patient waiting on a new ear mold, having a same-day mold would help fill the waiting gap. As an audiologist, I believe that every day should be a hearing day, so why miss out on all that hearing? Usually, the patients that require ear molds coupled to their hearing devices have more significant hearing problems and need their hearing aids working well all day, every day. If their ear molds need servicing, going a week or two without appropriately fit hearing devices would cause a significant hindrance on their daily life. For most patients, loaner hearing aids will suffice, but if the patient requires a mold, the loaner hearing aid likely won’t provide enough power. By providing a same-day ear mold at my clinic, I can ensure my patients can continue to hear well, no matter their level of hearing loss. I feel that this type of clinic feature meets best practice guidelines, and should be provided to patients.

Another great advantage of same-day molds could also be used to trial amplification with patients that require high output devices. With same-day molds, there is no need to use an uncomfortable foam tip coupled to a behind-the-ear power hearing aid or a poorly fit receiver-in-the-canal hearing aid during a trial. A same-day ear mold could be made in office and fit to a power hearing aid, allowing patients with a severe to profound hearing loss experience better hearing as if they had custom made molds from a lab.

Same-day molds can also be used in low resource settings to help fit individuals with donated behind-the-ear hearing devices. Low resource areas often have a stock of donated traditional behind-the-ear hearing aids, but no effective means of creating ear molds. Often these behind-the-ear hearing aids go unused, due to the lack of properly fitting ear molds. The open-source method discussed further in this paper for creating same-day ear molds can be used as a solution for better utilizing donated behind-the-ear hearing aids.

Same-day ear mold method

One of my favorite hobbies is 3D printing and design. I wanted to utilize 3D printing in this method, as 3D printing is affordable, versatile, and ubiquitous regardless of your geographical location. Nowadays, 3D printers have become a much more globally accessible tool, and are often marketed as a consumer good with little to no tinkering to get started. Most local libraries have 3D printers available for public use, too. Furthermore, low resource areas have adapted 3D printing as a means of manufacturing, and often use recycled plastics as the 3D printing “material”. This method works by 3D scanning an ear impression and then 3D printing the scan with a soft or hard material.

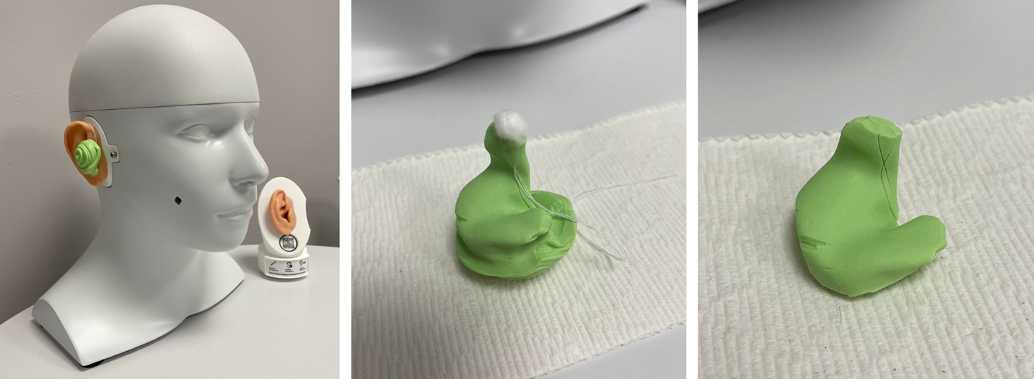

In order to explain this method and later validate it, I will be using the Clinical Assistant for Research and Learning, also known as CARL, created by AHead Simulations. By using CARL, I will be able to validate this method with real ear measurements. I first start by taking a standard impression of the ear, then with a sharp knife, I cut off the excess parts of the impression that I don’t need. You probably noticed a small split on the concha area of the ear impression (Figure 1). As you will soon see, this can be fixed digitally on the next step.

Figure 1. CARL with ear impression material setting in the ear. After the impression has set, excess parts are trimmed off. Hearing Beyond, Toronto (own photo).

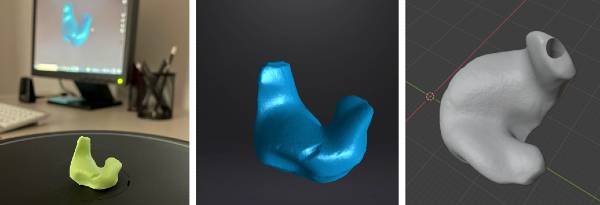

Next, using a 3D-scanner, I make a 3D scan of the shaped ear mold. There are a lot different 3D scanners on the market. Some low-budget scanners even use the camera on your smart phone to take a scan. Newer smart phones that come with LiDAR cameras tend to take better 3D scans than smart phones that have standard cameras. At my hearing clinic, I use a stand-alone, middle-end scanner called the Einscan-SE. This scanner has a very high accuracy, which is important when scanning a small item like an ear impression. Better resolution scanners will create a more accurate ear mold. 3D scanners work by taking several snap shots of an item at different angles, and stitching the snapshots together to make a digital 3D object. After getting an ear mold scan, I make some minor digital adjustments to fix any blemishes that the impression had, and add in a tubing bore hole through the mold. Remember the split in the concha section of the ear impression? Digital touch-ups removed it in a few mouse clicks (Figure 2). I use a free and open-source program called Blender to make my digital adjustments.

Figure 2. Ear impression being scanned and digitally manipulated. Hearing Beyond, Toronto (own photo).

The final step is to 3D-print this ear mold file. 3D-printers are loaded with a spool of material, also known as filament. 3D printers work by pushing filament through a very hot nozzle which temporarily melts the material and molds it to the desired shape (Figure 3). In order to make a soft ear mold, I use a rubber-like filament called Recreus FilaFlex 70A, which has a Shore 70A rating. Using this material in 3D printing creates an ear mold that feels similar to Formaseal. As a technical note, printing with soft materials is trickier than printing with hard materials. When printing with soft and rubbery materials, it is important to use a 3D printer that has a “direct-drive” extruder, instead of a “Bowden” extruder. Direct-drive extruders “push” the material straight through the hot nozzle, which allows a 3D printer to work properly with soft materials. Bowden 3D printers push the material through a tube first before the hot nozzle which causes jamming issues with soft filaments. 3D printing ear molds with hard materials is easier, but soft materials are often the most comfortable when worn in the ear.

Figure 3. 3D printer extruding filament to make a CARL ear mold. Hearing Beyond, Toronto (own photo).

After 3D printing the mold, I ensure it fits properly. I will secure ear mold tubing inside the tube bore, and then fit it to the patient’s ear and hearing aid. Real ear verification can then be performed to verify the hearing aid fitting. CARL seems to love the fit!

Figure 4. Finished ear mold beside original ear impression, and CARL fit with the ear mold, undergoing real ear measurements. Hearing Beyond, Toronto (own photo).

For this article, real-ear measurements were performed on CARL fit with an ear mold and coupled to a power hearing aid (Bernafon Leox 7 Ultra Power) (Figure 4). A flat, severe (80dB HL) hearing loss was programmed for real ear verification, and the responses were able to meet DSL 5.0 adult targets without feedback.

Usually, it takes around 2 hours to 3D print a left and right ear mold, but this is heavily dependent on the size of the mold and the type of material used. For example, if you wanted a canal mold instead of a full shell mold, the printing time would be quicker. Also, 3D printing with soft materials (like Recreus Filaflex 70A used above) is a lot slower than 3D printing with harder materials. Recreus Filaflex 70A is a type of Thermoplastic Polyurethane (TPU), and this material complies with the European regulations and FDA regulations for food and skin use. TPU is also used by ear mold labs to make molds, and is often used with patients that have very sensitive ears. Some other materials may not be rated for skin/ food use, so it is important to check with the manufacturer. Softer materials have some flex to them, and tend to be more forgiving on 3D scan imperfections and feel more comfortable in the ear (Figure 5).

Figure 5. Filaflex 70A flex demonstrated. Hearing Beyond, Toronto (own photo).

From my experience, these ear molds are as durable as a lab made formaseal mold. As a test, I’ve submerged an ear mold in a saline solution for 2 months, and its structural integrity was uncompromised. Another factor to keep in mind is that better quality scanners will provide a better quality fit. The scanner I use has a dimensional accuracy of 0.1mm, which is usually sufficient for creating an appropriately fit ear mold. I made a pair of ear plugs for myself, and they feel comfortable even after extended use (Figure 6).

Figure 6. A 3D printed Filaflex 70A ear plug worn on ear. Hearing Beyond, Toronto (own photo).

Benefits of 3D Printing Same-day Ear Molds

Current same-day ear mold products on the market require you to buy a 2-part mix kit, but tend to be finicky when it comes to embedding tubing into the mold. The patient needs to be present for the mold to be made, and you can only make adjustments to these types of products the old-fashioned way: with a grinding or buffing wheel. By using a 3D scanner, the ear impression is saved as a digital file, and any adjustments you want to make can be made on the computer with exact accuracy. If you wanted to add a vent, you can program that into the file. If you wanted to make speakers embedded into the ear molds, an appropriate adjustment can be made digitally to fit these components in. If the ear mold is not fitting properly, adjustments can be made on the scan file, and the ear molds can be 3D-printed again. The whole process doesn’t need to be repeated like the other methods. Furthermore, if you have impressions on file for a patient, they can be scanned and printed without the patient having to be physically in the office.

One of the biggest advantages to this method is that it is open-source. The software, hardware, and materials (and alternatives) used in this method can be accessed by anyone, without having to buy proprietary 2-part mixes each time you want to make an ear mold. This allows same-day ear molds to be accessible and available to any hearing healthcare professional.

3D printing has become a highly adopted method of manufacturing in low resource areas. I work with an organization called Glia, which increases the access of high quality medical supplies and devices in low resource settings by utilizing 3D printing. Many countries have adopted 3D printing to make stethoscopes, otoscopes, and tourniquets in-house, in order to provide themselves with high quality medical tools to treat patients. By adapting 3D printing as a means of production, countries can be self-reliant and manufacture high quality medical devices and supplies locally. Quite often, behind-the-ear hearing aids that require an ear mold are donated to developing areas. Without an ear mold, these kinds of hearing aids won’t function properly. Most of the time, these behind-the-ear hearing aids are fit by reshaping old donated ear molds, which would likely not provide an adequate fit. By making the ear molds on-site, these behind-the-ear hearing aids can be effectively fit to help people hear well. 3D printing properly fitting ear molds can help provide equal care throughout the world.

Limitations

One limitation is the printing speed. Consumer grade 3D printers are a type of additive manufacturing and work sort of like a glue gun pushing material out, waiting for it to dry, and putting more material on top of it. It’s slow, and it takes time to 3D print items; it’s definitely not an “instant” solution. Furthermore, this method struggles to create ear molds for very narrow, small ear canals. The smallest size CARL ear was used in this article to push the limits of the method, and an effective ear mold was made and validated. However, 3D printing does have limitations, and this method likely cannot accommodate even narrower ear canals.

Also, depending on the type of material you use, the availability of different colors may be limited. For example, Filaflex 70A currently does not come in beige, cream, or brown color. Furthermore, 3D printed items often have a “line pattern” along the sides, which can be seen as ascetically unappealing.

How You Can Get Started

To get started, I recommend trying on a simple 3D printed ear mold of your ear. Get an impression made of your ear, and cut off the parts of the mold that you don’t need. Download a 3D scanner app off of your smart phone’s app store. I recommend trying to find an app that says it can scan the shape of an object as well as its dimensions. After scanning your ear impression, you should get a “.stl” file, bring this file to your nearest library that has a 3D printer, and have the file printed! The end result will be your first 3D-printed ear plug! If you like the process and think it would be beneficial in your clinic or for your use, you can invest in higher quality machines and start producing same-day molds yourself!

Summary

Same-day ear molds are a useful clinic feature that can help hearing healthcare providers go beyond the practice standards to provide significant hearing benefits to patients. The method discussed in this article uses open-source hardware and software, allowing any hearing healthcare professional regardless of geographical location to make properly fitting, high quality ear molds for their patients. Same-day ear molds can also be used in-clinic to help patients receive appropriate amplification if their current ear molds need servicing or if they are waiting for a new ear mold order. In addition, patients can benefit from same day ear molds using them in hearing aid trials requiring a high amount of amplification. Globally, 3D printing has become an increasingly popular means of fabrication, and can be applied to hearing health care to allow patients better access to properly fit amplification and hearing devices.

References

Diles, B., Diles, W., & Jasa, A. (2020). The hearing aid test drive: a whole-practice approach for the new consumer. AudiologyOnline, Article 26528. Retrieved from https://www.audiologyonline.com

Citation

Talarico, F. (2021). Going beyond best practices: same-day custom ear molds. AudiologyOnline, Article 27853. Retrieved from https://www.audiologyonline.com