Learning Outcomes

After this course learners will be able to:

- Discuss how 3D scanned ear images are used as a tool during hearing aid consultation to engage, educate, motivate potentially improve outcomes, communicate value and differentiate their practice.

- Describe how custom hearing devices could help providers differentiate and segment their offerings from over-the-counter options.

- Describe how Otoscan utilizes two different lasers to obtain a complete and accurate scan of the patient's ear canal.

Introduction

Today, we will be discussing Otoscan 3D Ear Scanning. Before we dive into the presentation, I want to provide a quick overview of Otometrics, the company that manufactures the Otoscan. We have an expansive product portfolio, with five main product lines connected by proprietary software and supported by a dependable software and service team. We offer hearing care professionals products related to:

- Fitting

- Hearing assessment

- Screening

- Balance

- Sound rooms

History of Digital Ear Scanning

In order to comprehend why digital ear scanning is important, we must first understand the history. In the early 2000s, the Navy solicited universities with a grant for 3D scanning, because they had problems providing Navy personnel adequate sound protection on their war ships. One of the universities that answered the call for the grant was Georgia Tech. An engineer at Georgia Tech named Karol Hatzilias specialized in 3D technology. He contacted the Navy and was awarded the grant to develop 3D scanning for the ear. He invented a way to scan small holes with a ring laser and translate that scan into a 3D model in real time.

The Navy saw this technology as an optimal process for providing custom devices to their personnel more efficiently and effectively. Previously, the process for sending out ear impressions and creating molds for their Navy soldiers was laborious and time-consuming. Once an impression was taken, it needed to be shipped out via air delivery, or they needed to wait until they arrived at a port to hand deliver the impressions. From there, the impressions are sent to the manufacturer of the molds. The manufacturer takes the impressions, and they sculpt it or change it from silicone to an STL file (the type of file needed to print these molds). From there, the molds are delivered back to the ship. This took weeks, sometimes months. In cases where the molds did not fit properly, they had to be remade and this process occurred all over again.

The Navy determined that there needed to be a better way of producing ear protection for their pilots and personnel exposed to heavy noise exposure. With Otoscan, this process has been streamlined. We scan the ear with the Otoscan. The STL file goes up into an OTOcloud portal. The file is then taken out of the cloud, printed and sculpted on the ship, and distributed back to the personnel. Everything is done on-site, eliminating the time-consuming shipping back and forth as well as the need to wait until port.

Since this method has been successfully implemented on Navy ships, our next thought was, "Why not take Otoscan to the hearing clinic? If it could be done on a ship, we should be able to do this in the clinic." Currently, the traditional order process in clinics is to test the hearing, take the impression, ship it to the manufacturer, change it over to the STL file, and finally ship it back to the clinic for fitting. Again, this is too long of a process. We can streamline the process and make it more efficient for your clinics by following the Navy's model. We can look at the ear, scan, test into the Cloud, and then manufacture the STL file and print and sculpt the device on site.

Industry Changes

In January of 2017, the Hearing Review published an article comparing hearing aid unit sales in the United States between 2011 to 2016. They found that from 2011 to 2016 there was a decrease in customs, especially in ITEs (from 15% down to 8%). There was also a decrease in traditional BTE usage (from 35% down to 15%). Furthermore, there was a significant increase in RIC/RITE usage (from 35% up to 66%).

Hearing aid manufacturers are not receiving as many custom orders. One of the reasons is because younger audiologists coming out of universities are not being thoroughly trained in making impressions. These new audiologists arrive in the clinic and they're not feeling comfortable with taking impressions. Instead, RICs are so much more convenient to fit on a patient. All you need to do is go to the shelf and get a large, medium, or small dome and put it in the patient's ear. Is this the most appropriate solution for each patient? Maybe or maybe not. If someone is not used to making custom products and they always use domes, they may be fitting their patients inappropriately, resulting in inadequate hearing outcomes.

Concerns and Trends

Over-the-counter hearing aids are soon to be a reality. The FDA Reauthorization Act of 2017 that was signed by Donald Trump includes an Over-The-Counter Hearing Aid Act which mandates that the FDA establish an OTC hearing category for adults (over age 18) with perceived mild to moderate loss. The FDA will pose regulations for this new category by August 2020. OTC hearing aids will use the same functional scientific technology as the hearing aids that clinics are currently using today. The user will be able to control their OTC hearing aids and customize them as they see fit. OTC hearing aids may include self-assessment tests and wireless technologies.

One common concern that hearing care professionals have is when patients learn that they can purchase hearing aids over the counter for half the price, what's going to convince them to buy the same product from an HCP? How are hearing care professionals going to compete with OTC products? Another cause for concern relates to baby boomers. This population expects high-quality services and individualized health care, and they are increasingly doing their own research. If baby boomers begin buying OTC hearing aids, the average selling price for hearing aids will shrink. We're also seeing a lot of clinics wanting to digitalize their patients' experience so that they can take that data and use it to become more efficient in their clinics.

Meet Otoscan

Otoscan is a 3D digital ear scanning solution from Otometrics. It was developed by hearing care professionals for hearing care professionals. HCPs want their clientele to have an excellent patient experience and achieve the best outcomes. Otoscan is one of the solutions that they can incorporate to their clinics.

The Otoscan is currently FDA approved for patients 18 years or older. We are in the process of obtaining pediatric approval, but it takes longer to get FDA approval for pediatrics. Also, during the scan, the patient does need to hold quite still. Toddlers and very young children are going to have more difficulty holding still during the scan.

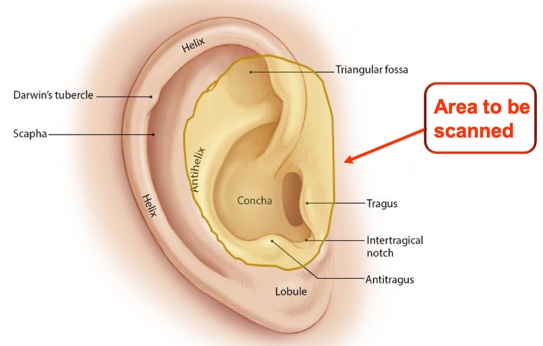

One way that HCPs can defend against OTC products is through customization and personalization. Rather than take the easy way and use domes, it is to our benefit to create a custom experience for our patients. With Otoscan, we can scan the patient's ear to customize their device and create a much better, more comfortable fit. The shaded area in Figure 1 shows the portion of the ear canal that needs to be scanned by the Otoscan device.

Figure 1. Area to be scanned by the Otoscan.

Custom products are not for everyone. In fact, domes are just fine for many of your patients. However, for patients who are "on the fence" between a dome and a custom product, creating a personalized solution may be the answer.

Key Features of Otoscan

Some of the key features of Otoscan include:

- Live In-Ear View

- Live 3D Rendering View

- Insertion Depth Gauge

- Gamified Training Application

- Easy Infection Control Process

- No Disposables

Otoscan Scanner Components

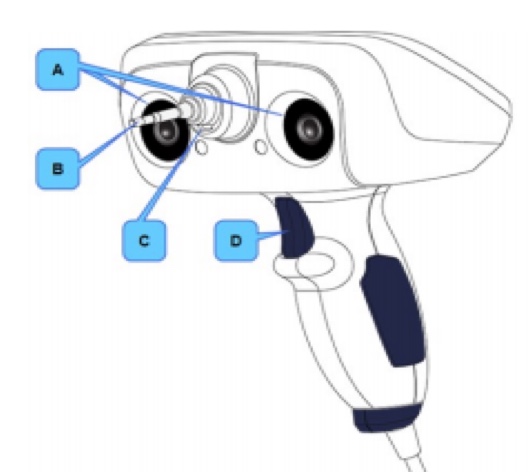

Figure 2 shows all of the components of the Otoscan as seen from the probe side.

Figure 2. Otoscan scanner components.

A. Tracking cameras. Cameras on either side of the probe detect the tracking ring of the headset worn by the patient. The cameras track the position of the scanner in relation to the patient's ear. To function properly, the cameras' view of the tracking ring must remain unobstructed.

B. Ring laser. Scans outwards from the tip of the probe. Scans the canal (in Canal Ring mode) and the curved portions of the pinna, such as the helix, sidewalls of the concha, and intertragal notch (in Concha Ring mode).

C. Line laser. Scans in front of the probe tip in a horizontal line (in Pinna Line mode), similar to a bar code scanner. It is used for scanning the flatter parts of the pinna, such as the center part of the concha bowl and ridges at the edge of the concha.

D. Trigger button. Selects the most common next action, based on the current state of the device. If more than one action is available, the most common next action is shown highlighted on the screen. For example, you will use the trigger to set the depth gauge and start a scan. During a scan, you can press the trigger to pause the scan.

I often get questions about the safety of the lasers, for example, if a patient has a pacemaker. They're absolutely safe. The ring laser is like an LED laser pointer that you would use when you are giving a presentation. The line laser is the same type of laser used at grocery stores to scan barcodes. There are no health concerns or issues with either of these types of lasers.

Verifying a Complete Scan

The steps for obtaining a proper scan are as follows:

- Set depth gauge

- Canal ring scan

- Pinna line scan

- Concha ring scan

To begin, you would set the depth gauge to the target depth. The first area of the ear that you will scan is the canal using the ring scan. Next, you would scan the flatter areas of the outside of the ear using the line laser. Then you finish off scanning with the curvy parts of the outside of the ear. The scanner walks you through this process. You can manually go back and rescan any areas that are missing data points.

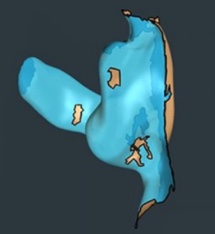

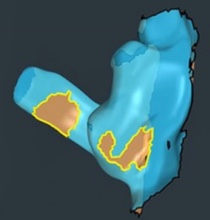

Figure 3 shows two screenshots of what you will see when you are using the Otoscan. The border color around the holes signifies whether or not you should collect more data in that area. In the image on the left, you can see that the border color is black. That means that we have enough data points to make this hearing aid or this ear mold. In the image on the right, the yellow border means that you need to go back and collect more data points to accurately make the device. It's a safeguard to make sure that you are making a proper scan and a proper device for your patient. It helps with decreasing your clinic's remake percentage.

Figure 3. Black border = good scan. Yellow border = incomplete scan.

Potential Contraindications

There are certain circumstances in which you should use the Otoscan with caution. Use of the Otoscan may be contraindicated in some cases.

- Excessive wax

- A small amount of wax is acceptable but, like with silicone impressions, a clean ear results in a better “impression”

- If excessive wax is present, either do not scan the ear or have the wax removed prior to scanning. After cleaning the ear, make sure that excessive moisture is not present prior to scanning

- If the patient has undergone recent ear surgery

- If there is discharge or evidence of infection

- If the patient is unable to remain still

- If the patient experiences a persistent cough reflex (Vagus nerve reflex)

- If the patient has a history of seizures, migraines or any sensitivity to a strobe light, reduce volume and have them close their eyes for the first portion.

Scanner System Components

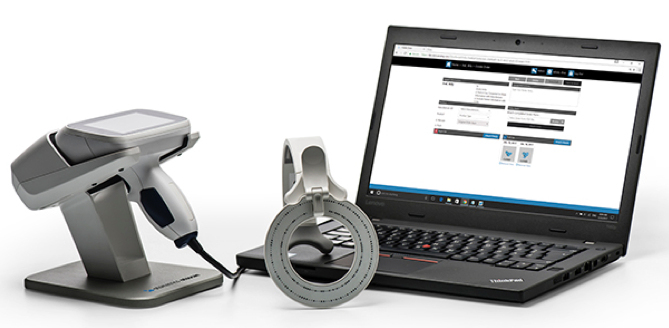

Figure 4 shows all of the hardware components of the Otoscan, which includes:

- Scanner with USB connection

- Single Application Locked-Down PC

- Session Manager

- Patient database

- Scanning

- Patient-worn tracking headset

Figure 4. Scanner system components.

On the left side of Figure 4 is the handheld scanner resting in its cradle. The scanner is connected to the laptop via a USB cable. For safety reasons, I would recommend that you always put the scanner back in the cradle when you are finished with it. If it falls on the floor, it is likely to break, as the ring scan is at the tip with a camera inside, surrounded by a thick layer of glass. In the middle of Figure 4, you can see the patient-worn tracking headset. This headset is used to provide a physical reference point for the scanner. Finally, the Otoscan system also has a single application, a dedicated scanning laptop. This is to ensure that we have full use of the graphic card, which uses about 86 percent of the backup card while scanning. In the future, this percentage may decrease, but this generation of Otoscan, we see the best results using the dedicated laptop that is provided. Although not pictured in Figure 4, you also will receive a practice ear with a stand, so that you can practice using the Otoscan before you start scanning actual patients.

The software component of the Otoscan is the Otoscan portal or Otocloud. It is a web-based portal software system. When you log into your dedicated laptop, your scan will be sent to the Cloud automatically, where it will remain for up to five years. You can use that scan as many times as you would like. For example, if used it with one manufacturer but you didn't like that result, you can license it to another manufacturer.

Otoscan Training

As with any new product, there will be a learning curve to start scanning. Think back to when you first started learning how to make impressions. You needed time to get used to it. Practice builds confidence and skill. It will take about five to seven patients for you to attain comfort in the basic scanning technique, and about 15 patients for you to build that skill set for confidence in scanning.

The online computerized training takes about two and a half to three hours at your own pace. There are 27 different modules that you need to work through. When you click on one of the modules, you will listen to and watch a brief video. The modules are "gamified". After you watch the video, you answer a question and practice that technique on the practice ear. When you're finishing your training online, you will be able to see statistics about your performance, including the percentage of practice scans that you have completed, your scanning times and the number of touches in the ear canal. The software also tracks your personal best times, best completions, and fewest touches in the ear. Using this data and the progress report, you can focus on improving your scores to become proficient with the Otoscan.

After you complete all of the modules in the online training portion, then you can start working with patients, or "real ears". When you begin, the length of time to complete a scan is around six minutes. As you become more proficient, your scan times will drop to less than two minutes per scan, on average. Compared to the average silicone process (which takes around ten minutes), using the Otoscan can prove to be a time saver for you and your clinic, and is more comfortable for your patient.

Otoscan Training Software

The training software, both in the dedicated laptop and the scanner, provides for interactive, real-time feedback to help the user become familiar with the device and techniques needed to efficiently scan a real ear.

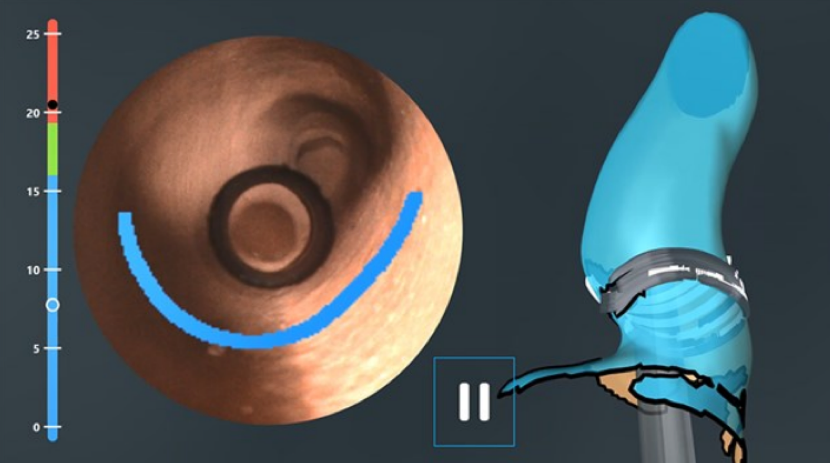

When scanning a real ear canal, you will see the depth gauge bar (left side of Figure 5). Blue indicates shallow insertion. Green indicates target depth. Red indicates an insertion warning. Target depth for males is 16-18 millimeters; for females, it is 14-16 millimeters.

Figure 5. Depth gauge bar.

Target depth is crucial in achieving a proper fit. The recommended target depth is based on literature reviews on average ear canal length, as well as on HIMS recommendations.

Status of Otoscan

Our current Otocloud Community partners include:

- ReSound

- Westone

- Emtech Laboratories, Inc.

- Microsonic

- Dreve

- Widex (UK only)

Ultimately, our goal is to have all the major hearing instrument manufacturers on board and accepting the scans globally. Other companies are in the midst of trialing the scanner, and they are continually sending us updates on their progress. They do have a process. It's not the fact that they cannot accept the file type, which is an STL file; it's the fact that when they receive the file, they need to know if they need to make changes to it. In the past, they were using the silicone impressions, and they would have to adjust those because those would expand the ear canal. With lasers, we're not expanding the ear canal. They want to make sure that the product that they make and send back is the top notch, best fit for your patient, and that there are fewer remakes. We project that in 2019, we'll see a lot more manufacturers coming on board and accepting these scans.

Patient Feedback

In Phase 1 of our trials, the Otoscan process received positive patient feedback:

- 92% of patients reported excellent/good comfort

- 94% of patients reported that scanning has a "wow" factor

- 74% of patients reported that it is better than the silicone impression procedure

Some of these patients were new and had no previous silicone impressions taken. As such, they were unable to compare the Otoscan experience to a silicone impression.

Operator Feedback

In addition to positive patient feedback, hearing care professionals are feeling more comfortable using the Otoscan. From the time the Otoscan was launched (April 2018), 70% of hearing care professionals reported operator success in reaching target depth with no gaps (only 7% had difficulties). In addition, 74% of HCPs reported success in utilizing the scanner system. We feel very good about these results because it's a brand new product. We are confident that those numbers will continue to increase with more use in the field.

Revolutionizing the Workflow

We believe that Otoscan is the future of hearing care counseling and will change the way you provide hearing care. With Otoscan, you have a powerful new tool in your toolbox to attract and engage more patients, while delivering personalized counseling and solutions in an efficient way.

The current workflow involves a passive delivery mechanism. First, you test the patient, then you counsel the patient about their hearing loss. Next, you decide on which hearing aids are most appropriate, take a silicone impression (if needed) and the patient ends up with hearing aids.

With Otoscan, we're suggesting a new workflow to engage with your patients. First, you look at the patient's ear, and then you scan the patient's ear, which engages the patient early on in the hearing aid process. As you're testing and presenting the information, you can use that scan as a counseling tool. When your patient walks in the door, they may have it in their head that they want the most invisible hearing aid in the market. However, when you finish testing and you present the test results to the patient, it may be that they are not the best candidate for a tiny hearing aid (either based on their type of loss or ear canal shape). Using the scan, you will be able to visually explain and counsel the patient to share your concerns up front about their expectations of the hearing aid. Their acceptance will be higher if you are able to show them the scan, versus just telling them they aren't eligible for the tiny hearing aid. In addition, being able to scan the patient's ears in the clinic avoids the hassle of sending their impressions off to the manufacturer, only to be told that they cannot create the hearing aid you requested due to the patient's ear canal size/shape.

This new workflow will enhance the patient/provider experience, making sure that you have an appropriate fitting for their hearing loss and that you meet their expectations. 3D ear imaging offers a step change in hearing care by frontloading the counseling and sales process and modernizing the supply chain.

We are currently conducting some trials to determine the degree to which Otoscan attracts patients. Based on our experience, we believe that you will be able to attract new patients to your door by offering them the experience of 3D scanning and improve the sound quality of their hearing aids. You can probably give the patient better hearing than what you would have with a stock mold. A personally fitted mold is going to improve the sound quality of their hearing aids.

With regard to delivery, the scan goes directly with the patient case to the supplier. The turnaround time is reduced and callbacks are minimized because the information is being delivered digitally to the manufacturer. They can read exactly what you have typed in your file notes and you will have fewer remakes and fewer callbacks.

In summary, converting a passive delivery mechanism into a strong asset for counseling and sales will prove to be of great benefit for your clinics. We strongly believe this new process will improve patient satisfaction, experience, and loyalty, as well as increase your revenue and referrals because when you have happy patients, they tell their friends. Overall, your process will be more streamlined using the Otoscan, and in the long run, it will save you time and money on handling ear molds and hearing aids. You're ensuring a better fit and reduced remakes and returns.

Financials of Otoscan

Otoscan has built-in features that allow for the optimization of processes by enhancing the quality of the origin of the value chain for custom hearing aids. What I mean by that is insertion depth. On all of our trials, we have seen four to six millimeters past the second band with a newly trained operator for the scanner. This is not a silicone impression replacement, this is so much more than that. This goes way beyond replacement. As I said, this is going to track, convert, and streamline your clinic. The manufacturers are ecstatic to receive longer impressions. Video otoscopic views for safer navigation. With Otoscan, you can see what you're scanning, and view all the information that you're going to use to make the hearing aids or earmolds, so that's crucial. The 3D rendering of the ear canal surface, so again great counseling tool for you and your patients to show them that. Moving towards the Otoscan can be used as an encouragement for making a stronger effort at securing a good scan the first time. The occurrence of remakes will be less. In our trial last year, remakes were roughly eight percent. Most hearing manufacturers say their remake is between 15 to 20 percent. So going from 15 to 20 percent on your remakes down to eight percent I think is really impressive. This is an advantage for clinics who fit many custom hearing aids. Instead of having a patient come back multiple times for remakes, you do it right the first time.

Otoscan Pricing

When you scan and send to the Cloud, the manufacturers receive the scan on their end. For the hearing care professional, the capital investment is $12,500 for a complete Otoscan system. Secondly, the $1,250 annual subscription for the Cloud that covers access for storage, ordering, software updates and maintenance. The first year of Cloud subscription is free. When I factor into the equation the amount of time you are saving and the number of patients you attract and convert, the Otoscan benefits begin to add up. What is going to make you different from your competitor? Taking the time to engage the patient in the process of selecting their hearing aids will differentiate your clinic. I want to say thank you to everyone who participated and attended the talk today.

Citation

Phillips, J. (2019). Otoscan - 3D ear scanning: the future is now! AudiologyOnline, Article 24421. Retrieved from https://www.audiologyonline.com