Editor's note: This course is an edited transcript of a live webinar. Download supplemental course materials.

Dr. Brian Fligor: Today’s topic is Making the Case for Custom. We will be listening to sound samples to hear acoustic differences between different kinds of earplugs. We all have an appreciation for differences between custom and non-custom solutions when it comes to hearing protection, but I want to make a clear explanation of the evidence that I believe makes the strongest case for custom earplugs.

This course is part of the AudiologyOnline 2014 Noise Induced Hearing Loss Seminar Series The other courses in this series include one by Dr. Billy Martin entitled, Tinnitus Care: What Should I Know When Starting to Provide Tinnitus Care? Dr. Jeff Ellenbogen, who is a neurologist at Johns Hopkins University, presented a course on non-auditory effects of noise exposure. Dr. Bob Ghent, who is an audio engineer, presented a course entitled, Management of Hearing Loss Prevention in Live Entertainment. All of these courses, and courses from the previous NIHL course series, can be found in the AudiologyOnline course library.

I would like to add a quick disclaimer before we get started. While my current employer is a medical device technology company, what drives my belief in this topic is my experience and knowledge as a clinical audiologist. For the past 14 years, my principle line of clinical work in audiology was in fitting custom hearing protection, consumer earphone custom solutions, in-ear monitors, and hearing aids. I am not representing any particular commercial interest today in this presentation.

Agenda

Today I will start with the pros and cons of custom hearing protection as well as consumer earphones. I will touch just a bit on hearing aids. This is about noise-induced hearing loss, prevention and mitigation, but people who are noise exposed end up using hearing aids and tinnitus maskers on occasion as well. There is some important information we can glean from the hearing aid literature.

We are going to talk about at-risk populations and how much risk is associated with the sound exposures. We will dive into the acoustics of non-custom and custom earplugs and listen to the acoustical differences. We are going to talk about the influence of earphone isolation on chosen listening level. This work has probably shaped my career more than any other work, and that is to understand how you can safely use your headphones.

The economics of custom products is also important. How much can the patient expect to invest, and what does this mean for the audiologist? I want to talk about utility of custom plugs in noise-induced hearing loss treatment, and then finish with some take-home messages.

Making the Case for Custom

Why are not all in-the-ear hearing protection devices custom made? There is evidence that we will discuss indicating that custom hearing protection devices, custom consumer earphones, and custom coupling of hearing aids perform better than non-custom devices. Almost by definition, custom should be more comfortable and more secure, meaning that the retention should be better in the ear. Custom solutions personalize the device and the care.

There are some non-economic interests as well. What we communicate to our patients should be centered around what kind of care are they receiving, not what kind of device they are buying. It is important to consider custom as another potential revenue stream. It is a portion of the service that we provide, and it is something that they cannot get anywhere else. This is certainly an area that differentiates us from consumer electronic equipment. As an audiologist, I consider myself a healthcare professional and am licensed as such. I am not selling commodities. I am caring for patients.

Barriers

Risk

It is important for us to understand and acknowledge the barriers to custom protection. Going custom requires additional time and equipment. It may involve exposure to risk, both for the audiologist and patient. I have researched in depth the risks associated with performing earmold impressions, and it does appear that many of the medical malpractice lawsuits brought against audiologists have to do with earmold impressions gone wrong. The other civil litigation that occurs frequently is when an audiologist misses a hearing loss or acoustic neuroma that was obvious based on testing. Earmold impressions come with inherent, significant risks. It is not something to be taken lightly.

Comfort

Custom is not always more comfortable than non-custom. It is not just the quality of the earmold impression; it is also what the lab does with that earmold impression. Did they deviate significantly from the earmold impression received?

Commodity

Non-custom hearing protection, or hearing aids, is easier to commoditize. If I am fitting a hearing aid to someone using a non-custom solution, they can walk out the door with the device the same day as the evaluation. These are typically receiver-in-the-canal (RIC) devices or mini behind-the-ear (BTE) with a non-custom ear tip. It is not just the evaluation, but it is also the initial fitting.

Adoption Rate

There is a low adoption rate amongst consumer earphones, especially for custom products. There are not many custom solutions for consumer earphones, and that is reflective of the fact that people like to buy their headphones in a store and take them right home. It is not necessarily understood that custom is going to be better. Maybe non-custom is good enough, and in certain circumstances, I would suggest it is good enough. However, I do believe that once you go custom, you never go back. Non-audiologist colleagues who have experienced custom products eagerly say, “Oh, wow! Now I see.”

That is what today is about. Let's see what information you can communicate to your patients and to the public to definitively answer the question, “Is custom really better?” There are some reasons to believe, yes, it is.

Populations at Risk

It is obvious that occupational noise exposures are still very prevalent since we keep talking about them and dedicating seminars to the topic. This is, in large part, what birthed the profession of audiology. The robust middle class through the 1950s created job opportunities in manufacturing, such as metal stamping, car manufacturing, and widget production. However, this type of industry oftentimes comes with unwanted byproducts, such as toxins, that the Environmental Protection Agency (EPA) has to regulate. One of those unwanted byproduct is noise.

Workplace Mandates

In the United States, it is mandated that hearing conservation programs be set up for workers who are exposed to the Occupational Safety and Health Administration (OSHA) permissible exposure level, or PEL. This means that any worker exposed to greater than or equal to 90 dBA for an 8-hour time-weighted average must be fitted with hearing protection devices. Additionally, all workers who are exposed to 85 dBA for an 8-hour time-weighted average must have access to hearing protection devices, although it is not mandated for them to use them.

There are very specific rules for monitoring and preventing hearing loss. If someone who is exposed to 85 dBA has a standard threshold shift, it then becomes mandatory for them to use hearing protection devices. I am not going to get into this today as it is beyond the scope of our conversation, but note that this is the kind of exposure we are talking about - people exposed to 85 or 90 dBA.

There are nine million workers exposed to noise in the United States at this point; that number has remained steady over time. As economic activity increases in different countries, the worldwide burden of noise-induced hearing loss is estimated to be around 40 million. These at-risk populations are not small.

The education and motivation component of a workplace hearing conservation program, particularly related to hearing protection device use, is the best way to mitigate risk for noise-induced hearing loss. Despite education and motivation being a strong piece of hearing conservation programs that requires work, research, and tremendous effort in mitigating hearing loss risk, noise-induced hearing loss is still among the highest work-related injury according to the Centers for Disease Control and Prevention (CDC) (CDC, 2014).

Noise-Reduction Ratings

To understand and describe hearing protection device performance, the EPA mandates certain ratings for the performance of hearing protection devices. Historically, the one that we have used and understand most is the Noise Reduction Rating, or NRR. When the NRR is calculated, there is a de-rating associated with the final number that is put on the package. That is to account for variability in peoples’ true hearing protection under earplugs or earmuff. Sometimes people achieve greater degrees of noise reduction than what is printed on the package, but quite often people get less.

One effort that is communicated among hearing loss prevention professionals is understanding differences between the NRR, which is a laboratory measure under ideal conditions, and the NRR self-fit or NRR-SF. The NRR-SF using ear muffs measures fairly consistently, mainly because the placement of earmuffs over your ears is going to be about the same each time, whether the experimenter put the earphones on you or you put them on yourself. However, the NRR-SF is much smaller than the lab-measured NRR with earplugs that are inserted into the ear canal. That is because there is quite a bit of variability in insertion, and it depends on how much education and training the individual had prior to inserting earplugs. The NRR-SF may be only half of what the lab NRR is.

Personal Attenuation Rating

There has been a strong move lately within hearing protection to go to a field-measured personal attenuation rating (PAR), which is an individualized NRR. It is not an average across 10 subjects; it is for one individual. There is a Field PAR or a Field MIRE (f-MIRE), which stands for microphone and real-ear measure. This is a move to acknowledge the variability associated with hearing protection devices. The NRR, in theory, is reflective of how much sound isolation a person is getting, and that allows you to predict how much noise exposure a person gets under the earplugs. However, that makes some assumptions that may not hold true because of variability.

Music Exposures

As an extension of our populations at risk, think about music exposure. I want to create a differentiation between occupational noise exposures and music exposures. Someone listening recreationally would have a music exposure, while someone producing music as their job would have an occupational noise exposure. The differentiation is that the intent of the economic activity. Music exposures are the intent of the activity, whereas occupational exposures are unwanted byproducts.

We know the portable listening devices have free-field-equivalent (FFE) levels of 103 to 121 dBA. Dr. Portnuff published a paper in 2011 stating that the maximum output of earbuds with an iPod is 103 dBA; that has been supported by a lot of the literature. It is quite possible to achieve much higher sound levels with different earphones that have higher receiver sensitivities than the stock earphones that come with the player.

Over Exposure

Let’s think about how many people are at risk. We know that hundreds of millions of smart phones have been purchased worldwide. The literature shows somewhere between 15% and 50% of people who use a portable listening device exceed an 85 dBA weekly equivalent continuous level. This rate depends on the listening environment in which the person had their listing levels sampled. For instance, in New York City, some colleagues and I looked at listening level and duration of listening on the typical daily and weekly basis (Levey, Levey, & Fligor, 2011). We found that over 50% of people in our sample, which was 160 subjects, were exceeding 85 dBA for a weekly equivalent continuous level.

Rock concerts do not routinely exceed 140 dB peak SPL for audience members. They are getting, on average, around 103 to 105 dB, up to 117 dBA. I have done sound measures in different concert venues where the level is as high as 112 dBA for a normalized 8-hour-equivalent continuous noise exposure. That would equate to a 5000% dose, or 50 times what one might consider to be allowable. That is on the upper end. The musicians who are doing amplified performance on a soundstage get between 100 and 110 dBA. That is in large part because of the economic activity, and also because their performance is dictated by their ability to hear and monitor themselves auditorily.

I did some fairly extensive sound survey work at the Bamboozle Road Show in June 2010 (Fligor & Wartinger, 2011). Stage levels there ranged from 94 dBA to 108 dBA; that higher level was taken closer to the drum kit. It was interesting to note that there were a lot of amps on the stage, but none of them were plugged in; they were just there for looks, because all the performers had custom in-ear monitors. The stage levels were not that high, but the audience itself was. So why are concerts so loud? It is because the noise floor at the concert is loud; the audience at their quietest is roughly 90 dBA, and when they cheer, it is around 117 dBA.

What ends up happening is higher audience exposures. If someone attended the show for all 7 Road Show acts, they would have been exposed for roughly 4 hours with an equivalent continuous level of 105 dBA. That would equate to a 5000% noise dose, which is not small. If we were to put that on a time-weighted average for an occupational setting, the sound exposure would about 102 dBA for an 8-hour-equivalent continuous level. In other words, a 5000% dose is about 102 dBA for the audience. Maybe they are only exposed to that once every month or once a year, because it is a special event. The crew, however, may have about 200 exposures a year because this is their livelihood. Their exposures were about 99 dBA, but their total exposure time was 7 hours. Their total dose was about 2200%, or 22 times the allowable amount, which equates to a 98.4 dBA equivalent continuous level. All of these listeners are sound exposed and need help.

Adoption of custom hearing protection. Adoption of full-custom hearing protection (as in-ear monitors) is highest among professional musicians. That speaks volumes. If money is not an object, and if performance is imperative, custom has to matter because it has a nearly 100% adoption rate amongst professional musicians. If custom did not matter, you would see a mix of non-custom to custom. If custom did not matter, musicians would not be spending the money.

Outside of the professional touring musicians, there are orchestral musicians, drum corps, and chamber musicians where the musician’s own instrument or their neighbors’ instruments will exceed 100 dBA FFE when they are playing at fortissimo. This group happens to be amongst the lowest adopters of any hearing protection devices, principally because of self-monitoring needs and because they do not routinely have sound engineers to help them hear through in-ear monitors. Any idea of interfering with the musician’s ability to monitor their own performance is out of the question. They are not going to do it. It is ironic to me that the professional stage performers have the highest adoption rate, but the musicians who are playing in the symphony orchestras of well-known cities have the lowest adoption rate of any group.

Damage Risk Criteria

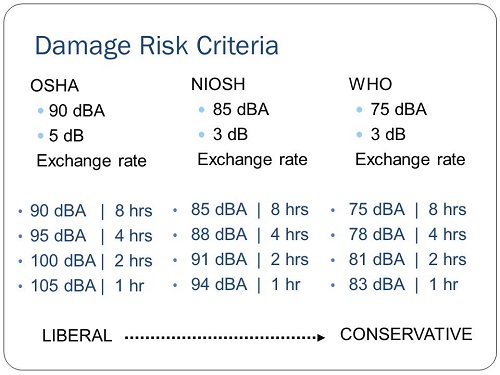

The damage risk criteria have been understood based on the seminal work of how loud is too loud and how long is too long. “Dangerous” listening levels are based on seminal research that looked at people exposed to 80 dB, 85 dB, 90 dB, 100 dB or 105 dB over the course of 1 year to 10 years to 40 years of 40-hour-a-week exposures (Prince, Stayner, Smith, & Gilbert, 1997). This data looked to see how many sustained a material hearing impairment, defined as a 25 dB average hearing loss across the speech frequencies. A material hearing impairment is considered a handicapping hearing loss.

The range of excess risk at 80 dB is 0% to 5%; 80 dBA is not safe. Excess risk at 85 dB was 10% to 15%, with a reanalysis done more recently by Prince et al. in 1997 saying that 8% of people exposed 85 dBA would sustain material hearing impairment. The OSHA PEL allows for between 21% and 29% of all exposed people to sustain a handicapping hearing loss. Let's consider that these exposures do not prevent hearing loss, even if there are limited levels or permissible exposure levels.

National Damage Risk Criteria

Figure 1 shows the breakdown of national criteria. OSHA has liberal damage risk criteria, which allows up to a third of people to sustain material hearing impairment. The National Institute for Occupational Safety and Health (NIOSH) allows 8% of people to have a material hearing impairment (Prince, et al., 1997). The World Health Organization (WHO) criteria, which are the most protective and conservative, aims to eliminate any permanent threshold shift at 4 kHz.

Figure 1. Damage risk criteria for OSHA, NIOSH and WHO.

Just Stick a Plug in It

Why can we not just stick any plug in it? Figure 2 shows that even teenagers can still have fun and rock out with earplugs in. Those earplugs can perform extremely well, due to the patented filter technology that can give 9 dB, 15 dB, or 25 dB sound isolation. They may also have certain acoustic components relating to compliance, inductance, and resistance.

Figure 2. Individual at rock concert with custom earplugs.

Non-Custom Foam Hearing Protection

An acoustic element that has to be considered for custom earplugs is the acoustic inductance offered by the sound bore of the custom sleeve. This sleeve offers excellent uniform attenuation, but only if it is long enough. If it is too short or if the sound bore is too narrow relative to the individual’s open ear, it shifts the natural ear canal resonance, creating significant distortion. It over-attenuates in the range of the unocculded ear canal resonance. If that sleeve is not coupled tightly to the ear canal wall, you get gaps, which are called slit leaks. A leak against the ear canal wall allows low frequencies in, and then you get no sound isolation in the lows. Not only do you lose protection, but you also have poor performance. If you have poor performance, you likely will not use the plug regularly.

If a person used a foam earplug at the Bamboozle Road Show, they would get a 50% noise dose instead of a 5000% noise dose. That looks good on paper, but would a person use a foam earplug for more than 95% of their exposed time? When using an Etymotic Research ER15 filtered custom plug, they are slightly overdosed at 158%. Are they more likely to use the ER15 earplug or a foam plug? Let's take a look.

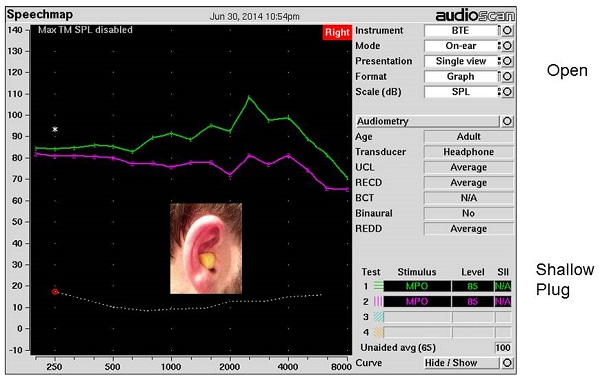

Figure 3 shows a picture of my ear with a standard foam earplug and shallow insertion just into the aperture of my ear canal. When we go to concerts, we see lots of adults and children with earplugs hanging outside of the ear canal. Those of us in the hearing loss prevention profession look at that and cringe, because, clearly, people did not learn to Roll, Pull, and Hold. This is where you roll it up, pull your pinna, insert the plug into the canal, let the pinna go and hold the plug in place until it expands. The real-ear measurements from this scenario are shown in Figure 3.

Figure 3. Real-ear measurements made with an open ear (green) and a non-custom foam earplug with shallow insertion (purple).

The green line (Figure 3) shows my open-ear response to an 85 dB swept tone, or the maximum power output (MPO), with the probe microphone down at the eardrum. You can see a fairly flat response with the ear canal resonance occurring after 2000 Hz. When the earplug is in place (purple), the real-ear response shows very little sound isolation up through about 600 Hz, then more sound isolation and a loss of my ear canal resonance.

What does that sound like? I am going to play some sound samples, so let's take a listen.

- Open ear, no earplug in place:

- Foam plug with a shallow fitting:

Audiophiles or audio engineers listen to that and say, “Make it stop!” The distortion is apparent.

The next recording is of a Blink 182 concert. The levels at the front of house where the sound mixing occurs were 105 dB.

- Open ear:

Here is the same sample from that concert using non-custom foam plugs.

- Foam plug, shallow fitting:

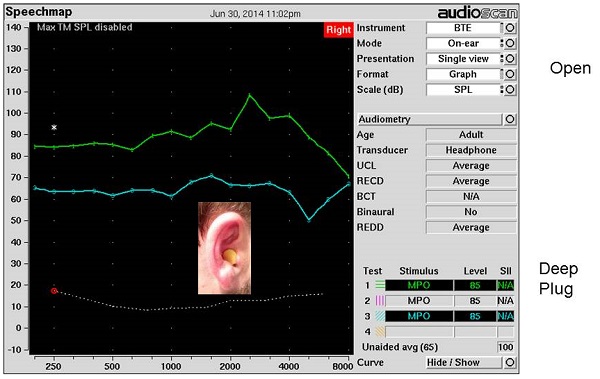

Is there any wonder why there is not even a 5% adoption of use of hearing protection devices in concerts in the United States? Let's say this person knows how insert their foam earplug correctly (Figure 4). We have the open-ear response in green and the sound isolation provided by a deeply inserted foam earplug in blue.

Figure 4. Real-ear measurements made with an open ear (green) and a non-custom earplug with full insertion (blue).

You can see the plug provides quite a bit of attenuation, but let’s listen. First is the sample from the Broadway musical.

- Broadway, open ear:

Here is the same selection with an appropriately fitted foam earplug.

- Broadway, foam plug deeply fitted:

Based on those samples, do you really want to stick a foam earplug in your ear when the intent of the activity is the music itself? Here is another sample, suited for the teen that attends rock concerts, with the open ear.

- Rock music, open ear:

Now here is the sample with the foam plug appropriately placed.

- Rock music, foam plug deeply fitted:

Do you think a teenager would really use these earplugs? Likely not.

Filtered, Non-Custom Hearing Protection

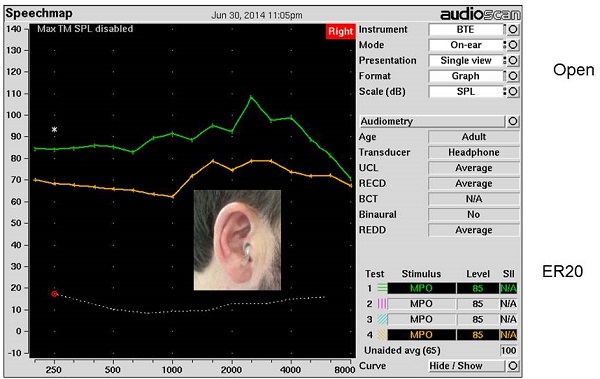

Next, we have an example of a filtered, non-custom plug. My open-ear response is shown in Figure 5 in green compared to the response with the non-custom Etymotic Research ER20 plug in orange.

Figure 5. Real-ear measurements made with an open ear (green) and a non-custom, filtered ER20 earplug (orange).

This non-custom ER20 is suggested to have better sound quality than a foam earplug. It does provide some sound isolating in the low frequencies, but not as much as a deeply inserted foam earplug. There is some approximation of ear canal resonance. Let's compare these options.

- Open ear, Broadway:

- ER20, Broadway:

In my opinion, the ER20 is much better sounding than the music through the deeply fitted foam earplug, played here.

- Deeply fitted foam earplug, Broadway:

Full Custom Hearing Protection

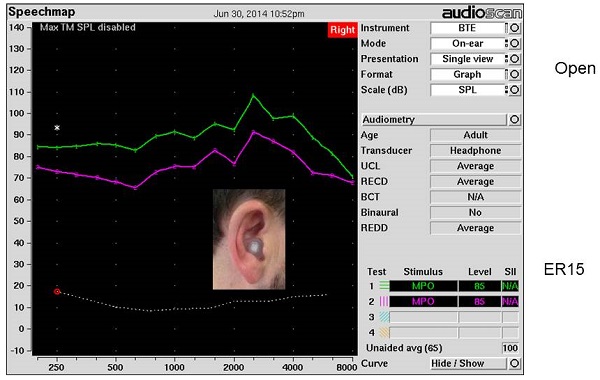

Again, Figure 6 is my open-ear response (green) compared with an ER15 musicians’ earplug. You can see that the attenuated response (in purple) follows my open-ear response (green) similarly.

Figure 6. Real-ear measurements made with an open ear (green) and a custom ER15 earplug (purple).

And now let's listen to the ER15 versus the open ear.

- Open ear, Broadway:

- ER15 Broadway:

To be clear, these sound samples are based on my actual measurements. This is not based on presumed flat attenuation. There is very little reduction in the high frequencies, and slight over attenuation at about 750 Hz, but it is uniform otherwise.

Full Electronic Hearing Protection

A full electronic earplug provides no attenuation until you reach inputs between 70 and 85 dB, and then it starts to provide either 9 or 15 dB attenuation, depending on the device. Figure 7 is the MusicPRO, a commercialized device from Etymotic Research. It comes with a standard tree-tip, but when I fit music enthusiasts, I make a custom ear sleeve. I do this to prevent slit leaks and maintain the integrity of the attenuation.

How much sound isolation do you lose with a slit leak? The fundamental frequency of the lowest piano key 27.5 Hz. The fundamental frequency of the lowest note on a violin is 196 Hz. That is below the measures I showed on the Verifit. We need to provide exceptionally good sound isolation if we want that music to go through the device as opposed to going around it. Sound mixing between the real ear and the attenuation device can create undesirable acoustic distortions. We want to isolate that as much as possible.

Figure 7. MusicPRO earplugs with custom sleeve (left); non-custom electronic earplugs (right).

Isn’t non-custom good enough sometimes? Etymotic Research notes that their device can act similar to the open ear for the 15-dB model, and even provide 6 dB of gain in the low frequencies for the 9-dB device. At high sound levels, the MusicPRO acts like a 35 dB passive earplug, assuming that the device fits the individual very well; keep in mind there will be variability between individuals.

Case for Custom

Custom devices reduce variability. Jennifer Tufts published some papers that describe the variability in sound isolation and how that dictates performance as well as comfort (Tufts, Jahn, & Byram, 2013; Tufts, Chen, & Marshall, 2013). Tufts, Jahn, & Byram (2013) showed that subjects with custom and non-custom devices both achieved good sound isolation. The baseline measurement was where the subjects fit the plugs themselves; then they went through some training on how better to insert the device. Prior to training as well as after training, the custom earplug provided significantly more consistent sound isolation across the most important frequencies where a person might have sound exposures, which was between 500 Hz and 2000 kHz. Interestingly, there was a statistically significant training effect for both custom and non-custom devices across frequencies, which is important for mitigating sound exposures. Choosing custom does not eliminate the need for training, but it can start the user off with better sound isolation, which then gets better over time with training.

The amount of attenuation provided is directly correlated with ear canal length (Tufts, Chen, & Marshall, 2013). However, there is an inverse correlation with how long it is and how comfortable it is. If the earplug went to the second bend, then the user had the highest sound isolation. Going past the second bend did not add to the amount of sound isolation. In some individuals, going very deep at all introduced comfort issues, and they did not tolerate the device as deep as it needed to be in order to achieve optimal attenuation. This indicates is a lower tolerance for deviation from an ideal canal fit. That is why both custom and non-custom plugs will not always provide optimal comfort.

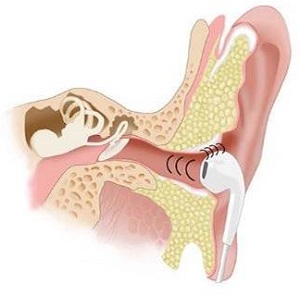

I would like to show some illustrations to make the point about custom versus non-custom. One non-custom solution, such as an earbud that comes with your mp3 player, does not seal the aperture of ear (Figure 8). That means you have gaps that allow low-frequency sound to bleed right back out. It also allows low-frequency background noise, such as road noise, to come in and cause masking. This causes people to listen loudly. However, it is not just about the low-frequency loss of bass and warmth to the music.

Figure 8. Non-custom earbuds allow low frequencies to enter and escape through gaps between the ear canal and the headphone.

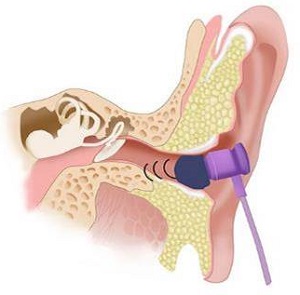

If the consumer headphone is inserted into the ear of a person with a curvy ear canal and pushed against the ear canal wall, the high-frequency sounds are lost because they do not bend around the curves of the ear canal as low frequencies do (Figure 9). Rather, they are absorbed into the skin and tissues, and the treble, which equates to the brilliance of music, is lost.

Figure 9. The high frequencies can be absorbed rather than bend around sharp bends in a curvy ear canal fit with a non-custom earbud.

In a well-fit custom product, regardless of the shape of the ear canal, the fidelity is maintained (Figure 10).

Figure 10. Fidelty of music is maintained in a custom earplug.

Acoustic Impact of Custom Hearing Protection

What is the impact of this? In quiet, 5% to 7% of people chose listening levels that were in excess of 85 dBA (Fligor & Ives, 2006). In just a little bit of background noise, more people with non-isolating earphones listen too loudly than people who had any level of sound isolation. Even more people listen too loudly in a restaurant when there is no sound isolation. In an airplane, 80% of people listen too loudly with non-isolating earphones, whereas fewer than 20% listen too loudly when using a sound isolating ER6i. In fact, the amount of sound isolation provided by the earphone predicted 37% of the chosen listening level. In other words, headphones that block out the background noise prevent listeners from turning up the volume louder than is safe.

The average amount of sound isolation provided by the non-custom ER6i earphone in our study (Fligor & Ives, 2006) was 24.6 dB. The range of sound isolation provided by this earphone for these subjects was 7 to 42 dB. The person getting 42 dB of sound isolation was able to moderate their listening level in almost any environment, but the person who only got 7 dB of sound isolation performed more like the person with an in-ear headphone.

Cory Portnuff and colleagues (2011) extended this work to teenagers. In the highest level of background noise (80 dB) with non-isolating earphones, 50% of the subjects listened too loud. When using a sound attenuating earphone, only 25% listened too loud, but the range achievable by the non-custom products is quite large.

Economics

To make a comparison, we pay $200 to $450 for our smart phones or mp3 players. Some people spend upwards of $10,000 on their podcasts, music and downloadable content. However, they then listen to that $10,000 of content on $40 earphones that cost about $1.50 to make. What if we were to advocate that people upgrade to a reasonable headphone for the amount of money they are spending on their music or on the player itself?

Custom sleeves cost between $100 and $200, and a quality earphone can run between $100 and $500. Disposable foam plugs are $0.20 per pair, but an individual can use two pairs a day, times 21 days in a given month of work. The bottom line is that these are not free, either.

If an individual were fitted with custom hearing protection devices instead of using disposable foam plugs at work, then the employer experiences a cost savings after only two years. The savings increase the longer the employee is with the same employer. Based on the evidence that I described (Tufts, Jahn, & Byram, 2013; Tufts, Chen & Marshall, 2013), custom products will be used more consistently and have more consistent sound isolation than disposable foam plugs. It lessens the likelihood of the employer having to submit a recordable noise-induced hearing loss to the Bureau of Labor Statistics. There is a nice calculator for custom hearing protection devices and cost savings at this website: https://www.washingtonaudiology.com/hearing-protection-cost-comparison.htm. I am not affiliated with this group, but I found it helpful and interactive.

Utility of Custom Earplugs in Noise-Induced Hearing Loss Treatment

Coburn and colleagues (2014) presented a paper at this year’s American Auditory Society meeting. They looked at the acoustic variability of occluded earbuds in receiver-in-the-canal (RIC) hearing aid fittings. They used non-custom open domes and closed domes. As expected, an open dome, which provides no sound isolation from the ambient noise and purposely allows the ambient noise a direct path past the hearing aid to mix in the ear canal, has little variability in this fitting. The closed dome provides sound isolation on purpose. When you do this, you are able to trap more of the amplified sound in the ear canal and extend the fitting range of those RIC devices to more severe losses. However, because the dome is non-custom, there was much higher acoustic variability. The acoustic properties of the closed dome are being assumed by the software, and due to the high variability from one patient to the next, that assumption does not always hold true.

This has implications for the gain characteristics and the amount of feedback management necessary. If you do not have a good seal in the ear when using the device as a tinnitus masker, the masking noise will leak out of the ear and reduce its effectiveness. All of this has an impact on the battery drain. You are running the hearing aids hotter than if you had higher consistency in the acoustic properties. When you go with a non-custom solution, particularly a closed dome, it increases the reliance on objective verification of your fitting. If you are doing non-custom products, it is imperative to do real-ear measurements. You are much more likely to achieve prescriptive targets and have good audibility with comfort in custom devices as opposed to a non-custom devices.

Summary

The non-custom solution is convenient in the short term, but I would argue that the cost is higher than what the convenience merits. The unpredictable performance gambles some incorrect assumptions, particularly related to risk mitigation for noise-induced hearing loss. If we assume that the earplug is providing 20 dB of sound isolation, but only provides 4 dB because it was not placed properly, then we may be saying these earplugs will protect hearing, when in fact, they will not.

If you go with a well-fit custom solution, it increases the likelihood of the earplug fitting in the ear and providing consistent hearing loss protection. Moreover, the individual will use it more routinely. That dictates what their protected sound exposure is, not what NRR the earplug offers.

Why do people listen so loud? Individuals listen louder than the competing background noise. Background noise is mitigated by having an isolating earphone. The isolation is more consistent when you have a custom device than a non-custom device.

From an economic perspective, it can be a win for the patient and a win for the audiologist. The devices cost us a little bit of time, but we are able to recoup costs and turn a modest profit. If I am fitting a non-custom device in a person’s ear, the focus ends up being more on the device than the professional service.

There is a valid fear regarding the commoditization of hearing aids. I would also argue there has always been commoditization of earphones and hearing protection devices. Customization offers a perspective of hearing health care and service in our practice. It is less about a commodity and more about health care.

References

Centers for Disease Control and Prevention (2014). Work related hearing loss. DHHS (NIOSH) Publication Number 2001-103. Retrieved from www.cdc.gov/niosh

Fligor, B. J., & Ives, T. E. (2006). Does headphone type affect risk for recreational noise-induced hearing loss? Paper presented at the NIHL in Children Meeting, Cincinnati, OH.

Fligor, B. J., & Wartinger, F. (2011). Musicians’ hearing program. Audiology Today, 23(3), 30-40.

Levey, S., Levey, T., & Fligor, B.J. (2011). Noise exposure estimates of urban MP3 player users. Journal of Speech, Language, and Hearing Research, 54, 263-277.

Portnuff, C. D., Fligor, B. J., & Arehart, K. H. (2011). Teenage use of portable devices: a hazard to listening? Journal of the American Academy of Audiology, 22(10), 663-677. doi: 10.3766/jaaa.22.10.5.

Prince, M. M., Stayner, L. T., Smith, R. J., & Gilbert, S. J. (1997). A re-examination of risk estimates from the NIOSH Occupational Noise and Hearing Survey (ONHS). Journal of the Acoustical Society of America, 101(2), 950-963.

Tufts, J. B., Chen, S., & Marshall, L. (2013). Attenuation as a function of the canal length of custom-molded earplugs: a pilot study. Journal of the Acoustical Society of America, 133(6), EL446-451. doi: 10.1121/1.4802896.

Tufts, J. B., Jahn, K. N, Byram, J. P. (2013). Consistency of attenuation across multiple fittings of custom and non-custom earplugs. The Annals of Occupational Hygiene, 57(5), 571-580. doi: 10.1093/annhyg/mes096.

Cite this content as:

Fligor, B. (2014, September). Making the case for custom. AudiologyOnline, Article 12959 Retrieved from: https://www.audiologyonline.com